Whale fenders completed its SCN600 cone fenders factory test in compliance with PIANC2002 guidelines with the production coming to end.

It is totally 30 sets cone fenders assembled with front panel. The test includes four parts: Raw material test, Dimensional check, compression test, Quantity check.

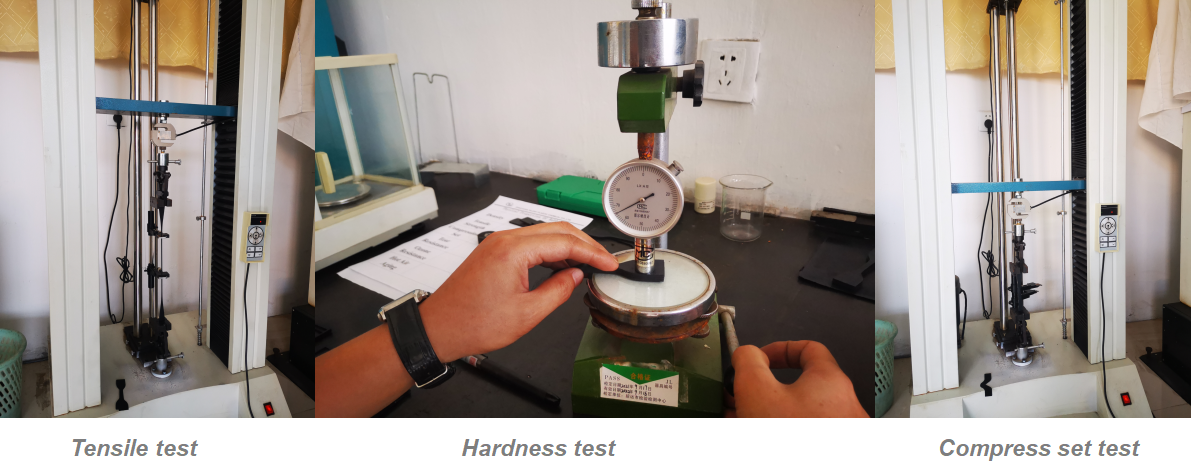

1,Raw material test:

Vulcanized natural and synthetic rubber (SBR), natural rubber (NR) or mixtures of both will be used in the fabrication of rubber fender.

Additive such as carbon black and anti-ozone agent etc. are to be added to the rubber compound to enhance the rubber fender’s resistance to seawater, ageing, ozone and ultraviolet rays etc.

The rubber material will be homogeneous in quality and free from any impurities such as foreign materials, bubbles, injuries, cracks and other harmful defects.

1)The rubber compound used for fender production shall comply with the requirements of Table below.

A) Physical properties of rubber and test result

TEST STANDARD | TEST ITEM | CONDITIONS | STANDARD VALUE | TEST RESULT |

ASTM D412 | Tensile Strength | Original | ≥16MPa | 19.15 |

ASTM Die C | Tensile Strength | Aged for 96 hours at 70℃ | ≥12.8MPa | 16.15 |

ASTM D412 | Elongation At Break | Original | ≥350% | 463 |

ASTM Die C | Elongation At Break | Aged for 96 hours at 70℃ | ≥320% | 408 |

ASTM D2240 | Hardness | Original | ≤78 Shore A | 65 |

Aged for 96 hours at 70℃ | Original value+6°Point increase | 68 | ||

ASTM D395 | Compression Set | Aged for 22 hours at 70℃ | ≤30% | 19.4 |

ASTM D624 | Tear resistance | Die B | ≥70KN/m | 101.75 |

ASTM D1149 | Ozone resistance | 50ppm at 40 O C at 20% strain at for 96 hours | No cracking visible by eye | No CRACKING VISIBLE BY EYE |

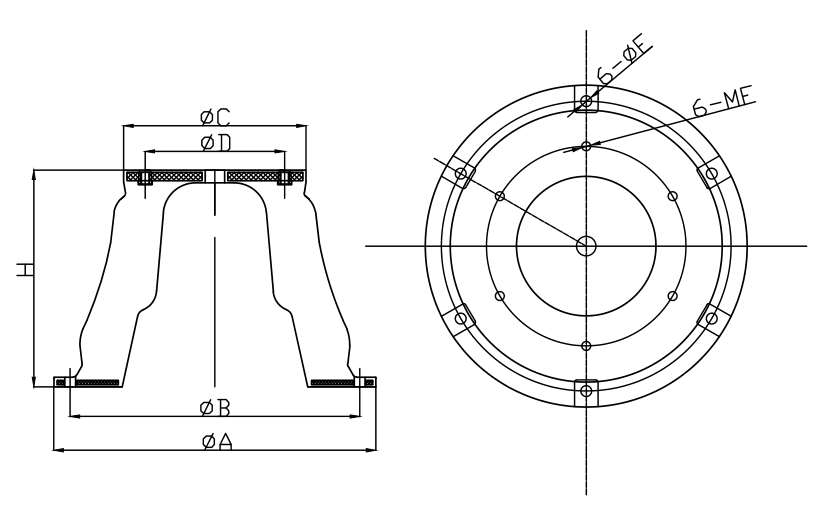

2,Dimensional check

3 sets fenders by ramdom as sample were done dimension check, The tolerance for the fender dimensions shall comply as follows:

Items | Outer | Inner | Length |

Tolerance | + 4% - 2% | +1% - 2% | +4% - 2% |

Table-2: Tolerance of Fender’s Dimensions

Specification:SCN600H unit:(MM)

Number | H | ØA | ØB | ØC | ØD | ØE | MF |

Standard value | 600 | 900 | 810 | 510 | 390 | 30 | M24 |

1 | 600 | 900 | 810 | 509 | 390 | 32 | M24 |

2 | 601 | 900 | 811 | 510 | 391 | 31 | M24 |

3 | 601 | 900 | 810 | 510 | 390 | 31 | M24 |

3,Compression test

Compression test is a vital step to prove the working performance. The fenders was put on pressure testing machine to simulate the real ship berthing, The performance of the Fender is expressed by the value of the energy absorbed during the compression of Fender up to the designed deflection and the maximum value of reaction load thus obtained.During the performance test, the fender will be subjected to a vertical force acting directly on the top surface of the fender.Compression stroke speed at 2-8cm per minute up to the designed deflection is to be repeatedly conducted for three consecutive testing. The load and the deflection in each test shall be recorded with the precision of 1.0 KN (0.1Ton) and 1mm respectively unless otherwise specified.Performance of fender is obtained from the average of the second and third test data.The average value shall be more than the designed performance value for the energy absorption and less than the designed performance value for the maximum reaction load taking into consideration of the plus minus ten percent tolerance.

RUBBER FENDER PERFORMANCE TEST REPORT

DATE OF REPORT | 23th Jun 2022 | MANUFACTURER | WHALE MARINE PRODUCT CO.,LTD | ||||

DESCRIPTION | RUBBER FENDER | SPECIFICATION | SCN600H Rubber Fender | ||||

TEST DATE | 22~23th Jun 2022 | TEST TEMPERATURE | 23oC | RH % | 55 | ||

TEST NUMBER | 184 | TEST PURPOSE | PERFORMANCE TEST | ||||

PRODUCT PERFORMANCE | RATED COMPRESSION DEFLECTION | REACTION FORCE (KN) |

REQUIRED VALUE | ≤426 | |||

70% | ENERGY ABSORPTION (KN-M) | ≥134 | |||||

TESTIING RESULT | RATIO | ||||||

SCN600H | REACTION FORCE (KN) | 421.76 | 3.06 | ||||

ENERGY ABSORPTION (KN-M) | 137.48 | ||||||

SCN600H | REACTION FORCE (KN) | 418.91 | 3.05 | ||||

ENERGY ABSORPTION (KN-M) | 137.33 | ||||||

SCN600H | REACTION FORCE (KN) | 417.42 | 3.04 | ||||

ENERGY ABSORPTION (KN-M) | 137.22 | ||||||

Whale fender as a one-stop marine fender suppliers, we commited to supplying the best value product. All fenders are tested strictly comply to the industry standard before delivery to our clients. As we always said, we deliver what we promise, to be the top trustworthy supplier.

Copyright © Whale Marine Product Co.,Ltd. All Rights Reserved | Sitemap| Powered by