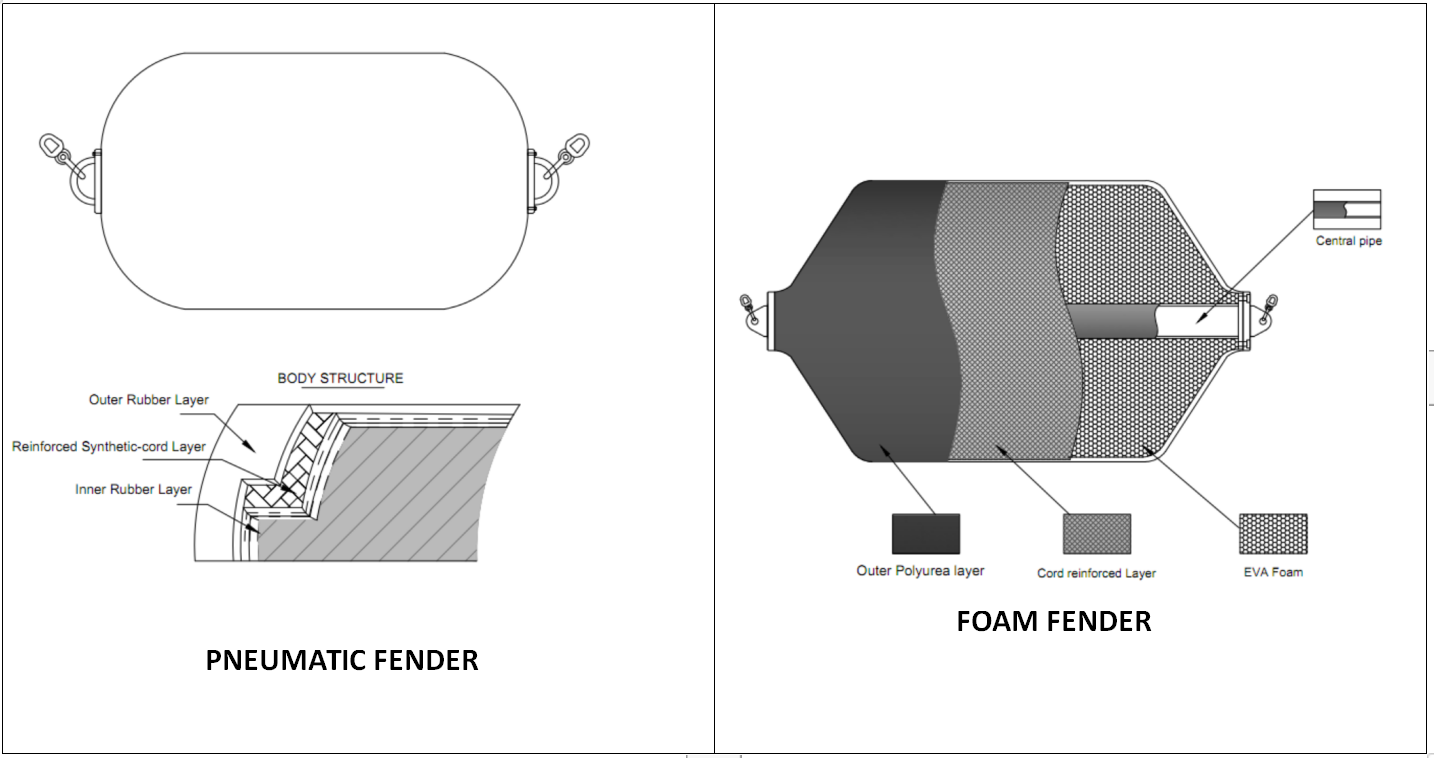

Both pneumatic fender and foam fender are a type of floating fenders which could be used for ship berthing operation. They are able to absorb the energy generated by the vessel while berthing through their deformation. Pneumatic fender is a air-filled fender made from compound rubber,versus foam fender is consist of a inside foam core and polyurethane spray at the appearance.

1, Structure:

2, Application:

Both of them could be used for ship to ship and ship to shore berthing operation. As a air filled fender with a light body, pneumatic fender is easy to deploy and transportation after deflated for temporary berthing like offshore ship to ship transfer operation. It is an ideal option for the Port with extreme tide variation as well. Foam fender has a solid foam filled body which make it unsinkable, the performance doesn`t reduce much even been punctured. It won`t leave any mark on the vessel hull after berthing, therefore they are more popular with ferry,cruise navy terminals.

3, Transportation:

The goods cost of foam fender is basically higher than pneumatic fender on the base of same size. However, the package volume of foam fender is much more than deflated pneumatic fenders. Pneumatic fenders could be loaded into general shipping containers after removing the air insides, foam fender with oversized has to be used for flat rack for transportation which the cost is quite high.

4,Maintenance:

Sorting the fenders keep them away from heat,acids, alkali, greases and organic solvents.

Especially,when storing the pneumatic fender more than three months without use, reduce internal pressure to about half of initial pressure(20~30kPa),so that the pressure will not rise too high due to atmospheric temperature. Do not deflate or fold.You have to check the pressure of pneumatic fender everything three months when the pneumatic fenders used in application. It is obviously that pneumatic fenders takes more labor and cost to do the maintenance.

Copyright © Whale Fender Limited. All Rights Reserved | Sitemap| Powered by